Projects

Pipe cleaning vehicle - entire redesign and conversion

Our client is operating a pipe-celaning vehicle to flush sewers and pipes.

Our client is operating a pipe-celaning vehicle to flush sewers and pipes.

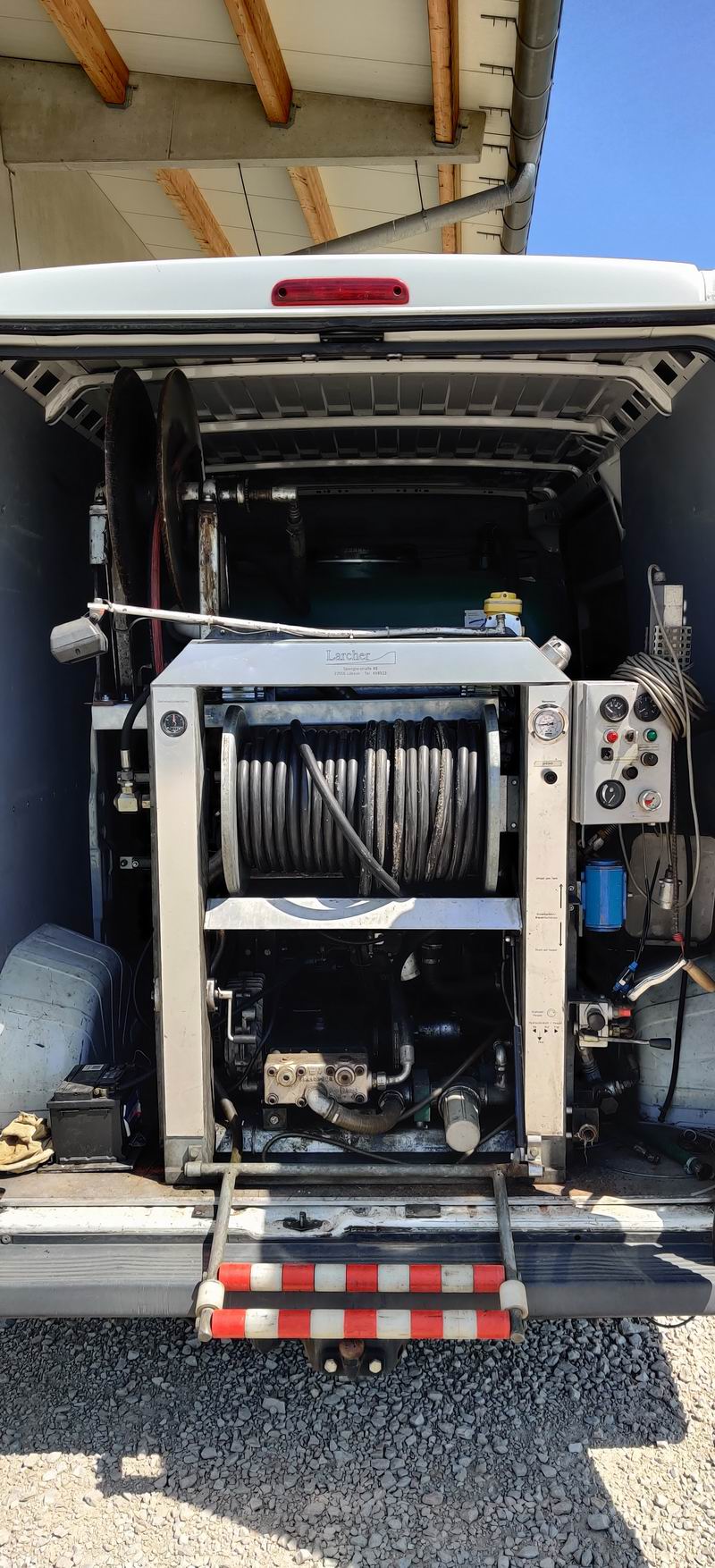

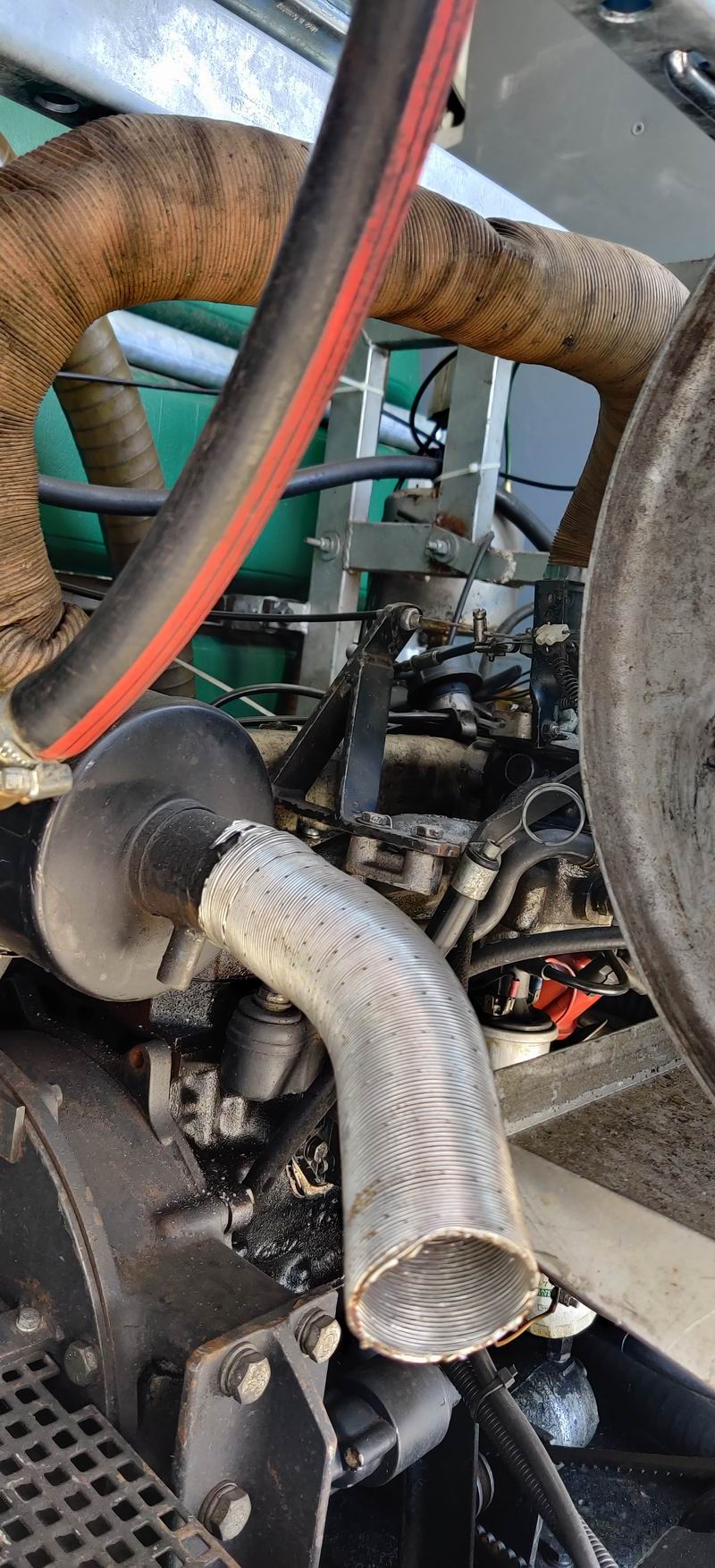

As delivered, the vehicle has a 1000l water reservoir, that is feeding a 3-plunger high pressure pumpe. An old Ford petrol engine, located directly behind the hose reel, is powering the pump. Radiatior, fuel tank, battery etc. are also INSIDE the compartment.

The waterpumpe was delivering 70lpM water at 150bar, allowing for 15 minutes of cleaning until the water is depleted.

The operator was forced to work directly besides a running petrol engine, suffering from noise, heat, blast and exhaust gas. Everything was build tightly, hard to deal in case of service or repair.

We were ordered to update the system to state-of-the art.

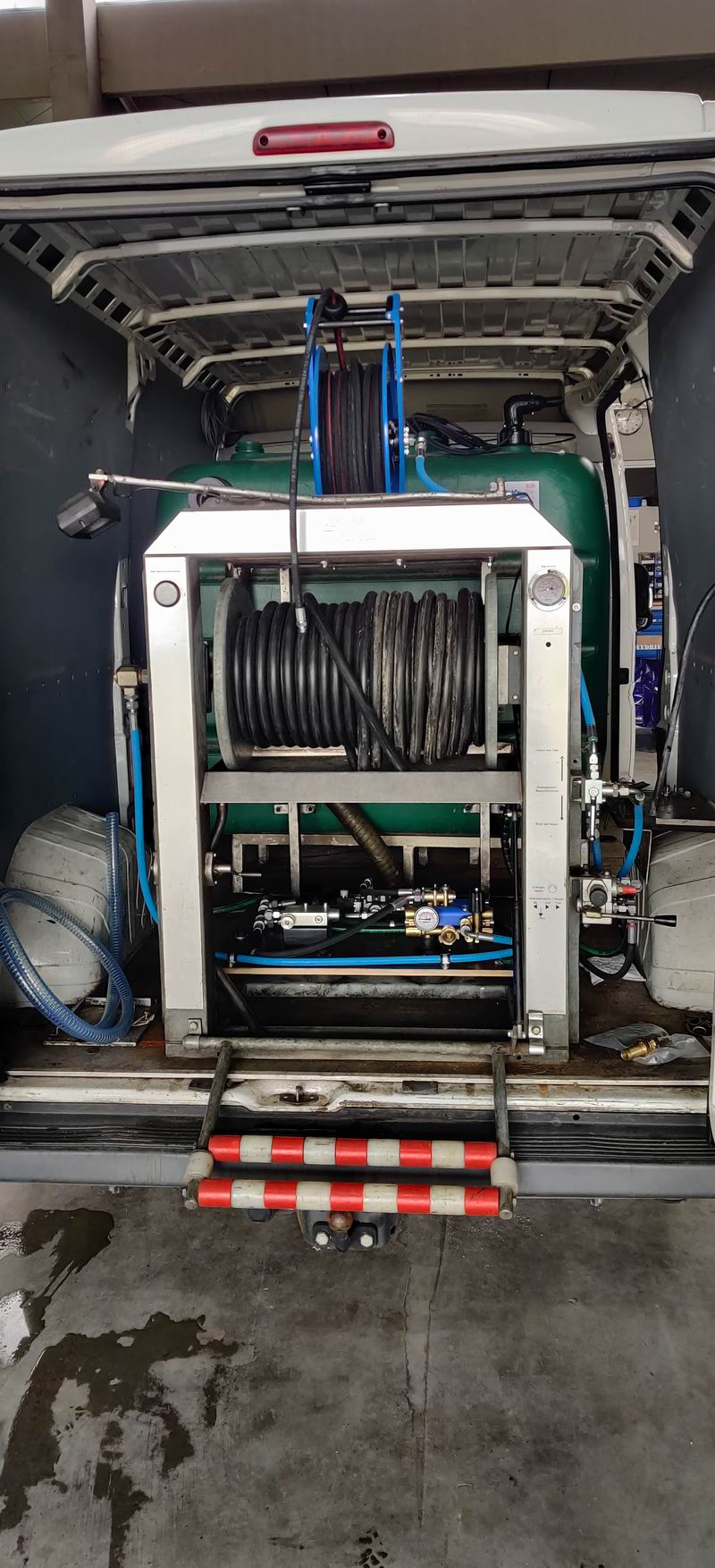

Our concept consisted of a hydraulically powered High-pressure Waterpump HPW250/30-40 from DYNASET. The old Ford engine will be removed completely, using the vehicle's main engine to power a hydraulic pump via a Engine-PTO, combined with an electronic RPM module to provide higher power during pumping operations.

Additionally a spray gun plus 20m hose reel was added, to allow for expanded cleaning operations.

To provide hydraulic oil, we mounted a 40l tank on an elevated basis. Oil supply is crucial fur hydraulic

pumps!

The entire hydraulic system (high-pressure water pump, flow control valve, hydraulic control valve) was mounted on a solid plywood deck.

When assebled, the entire working compartment looks much more pleasant:

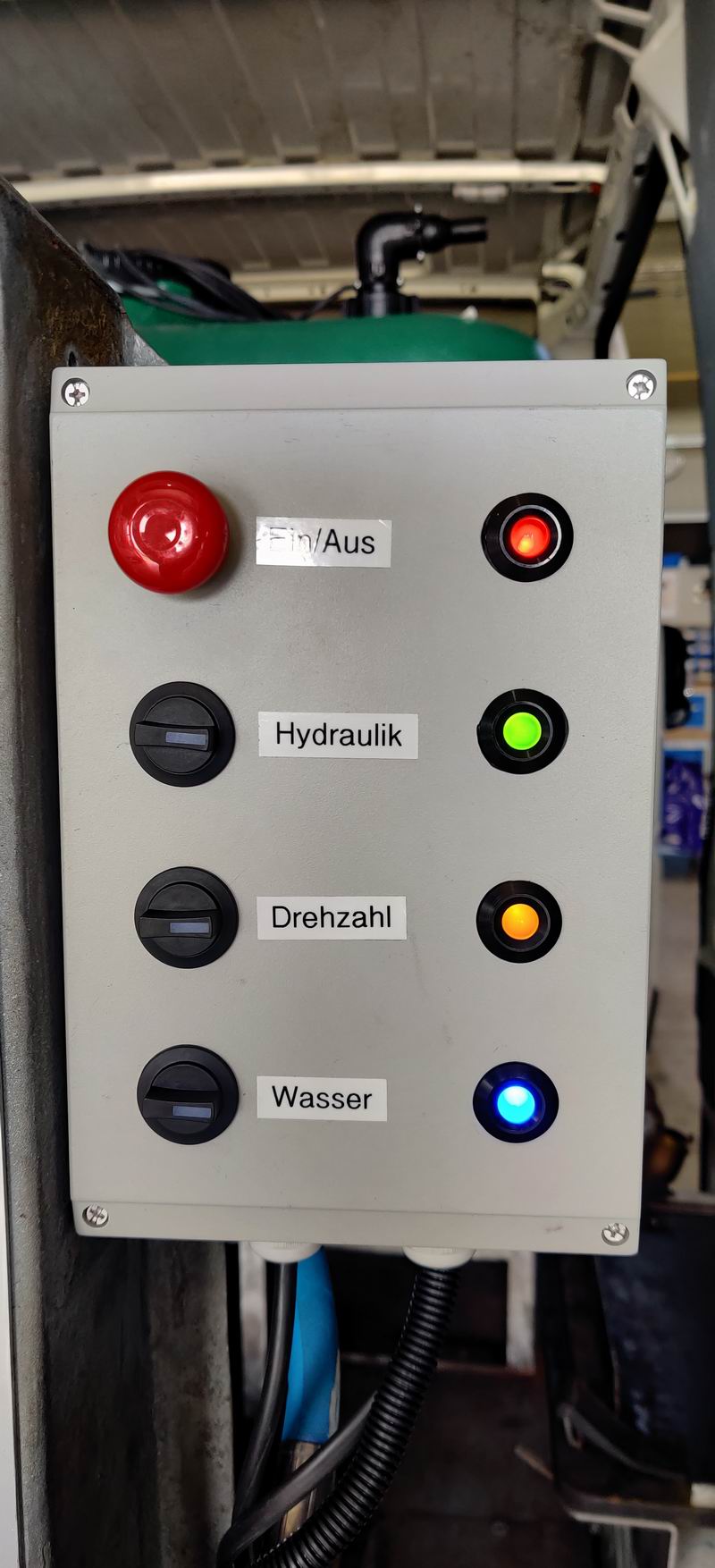

A control panel with clear indicators completes the system:

Functions work sequentially:

The functions are logically linked - if e.g. "Drehzahl" is being switched off, the waterpump will be automatically switched off as well.

Which benefits does this system have?

Even the old Ford engine was more than a Euro-pallette.....