DYNA-pax modular System

Description

Our DYNA-pax modular system are a configurable set of aggregates, providing an almost unlimited number of variants and combinations regarding power and energy supply.

You can dowload the complete vehicle pump kit catalogue HERE (NEW Catalogue!)

DYNA-pax is a synthetic term, put together from DYNA for Dynamical and pax short for "Packs".

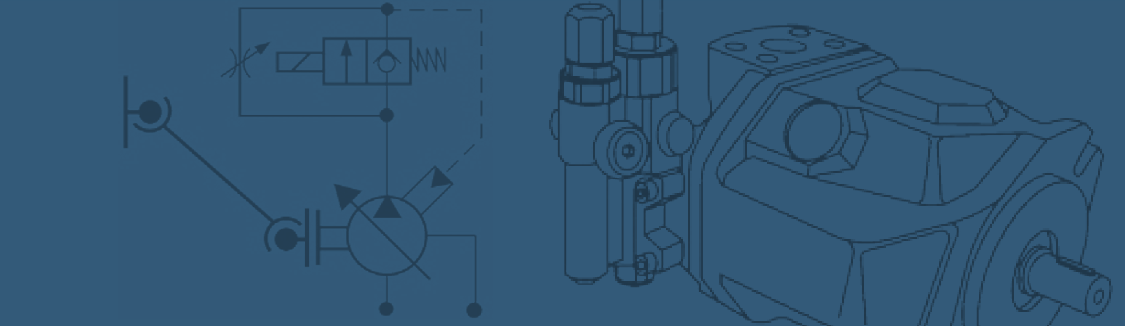

In combination with our ECU DYNA-BX you can convert your vehicle to a full-digital controlled power platform with functions like:

- Constant REVS (e.g. for operating hydraulic generators at constant displacement pumps)

- Constant pressure (e.g. for operating hydraulic machinery like drilling rigs that have varying power demand)

- Engine acceleration / high idle for stationary operation of higher loads

- RPM limiter or PTO shut-off to prevent pump damaga

- Conctant flow, power-following mode a.s.o.

To assist you in rough calcualtions regarding hydraulic system we published an Excel-Spreadsheet.

Power Input

This Element acts as power-input into a DYNA-pax unit. Input can be provided by different means like:

- V-Belt

- Poly-V-Belt

- toothed Belt

- Hydraulic Motor

- Petrol Engine

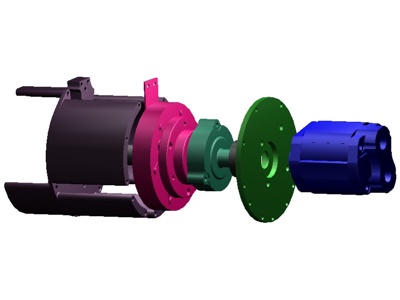

Coupling Unit

The Coupling Unit connects power input with the follow-uop stages. Four variants are available:

- electromagnetic clutch (100 / 130 / 240Nm)

- mechanical operated clutch (90 / 190 / 600Nm)

- support flanges / direct drive

- adaptor flanges

Stage 1

System Stage 1 is the place for units intended to convert mechanical input into a desired output. These are possible units:

- Hydraulic pumps

- Compressors

- Water Pumps

- Alternators

- Generators

Stage 2

System Stage 2 can adopt further units, similar to Stage 1. Stage-2-units always operate in parallel to Stage-1-unit and can currently only be placed behind a hydraulic pump with traversing driveshaft:

- Hydraulic pumps

- Compressors

- Water Pumps

- Alternators

- Generators

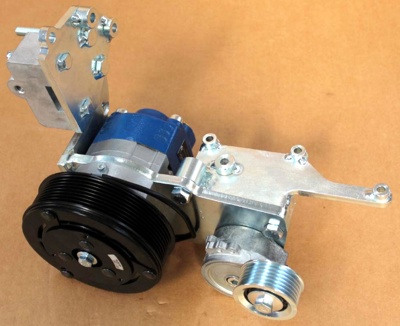

Standard Belt-driven PTO Kits

Product description

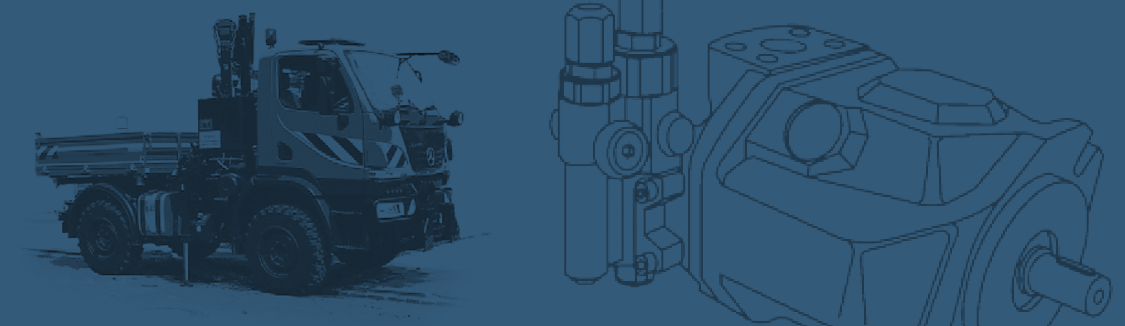

Hydralic Pump Kits for a wide range of vehicles

The kits include everything required:

- electrical magnet clutch 60Nm, 108Nm or 140Nm

- Hydraulic pump 8,5ccm (can be changed according your requirements)

- evtl. additional idler

- belt tensioner and support

- Mounting console and accessories kit

- belt

- water hoses and adaptors, if required

- radiator fan, if required

- thermoswitch, if required

You can dowload the complete compatibilty chart HERE (NEW - 2021 Catalogue!)

Performance data:

- 8,5ccm Hydraulic Pump (other Pumps available)

- standard 200bar, maximum 250bar

- ca. 7lpm at 800UPM

- ca. 21lpm aT 2500UPM

Example: Rotax CanAm-PTO